Wartsila 18V46 Dual Fuel Modification for Power Plant

In situ machining modification as part of complete block replacement

The 120-MW barge-mounted power plant in Haripur, Bangladesh, owned and operated by power generation providers NEPC and Covanta Energy, has been in operation since 1999. One of its eight Wärtsilä 18V46GD engines required significant repair work, including the supply of a fully reconditioned engine block.

Goltens was contracted to replace it and to overhaul and modify the replacement block to run on Gas as well as MDO and HFO. Goltens is not new to undertaking the most demanding repairs in the industry. Goltens located and inspected a similar engine block in a power plant in the Philippines and sent it to Goltens’ workshop in Singapore for a full overhaul and machining modifications. All modifications were completed utilizing Goltens’ In-Situ machining tools.

The full scope of work was carried out in three locations, culminating in the rebuilding of the engine and commissioning on-site in Haripur, near Dhaka, Bangladesh. This was an extremely challenging project that required complicated logistical arrangements and operations between the Philippines, Singapore and Bangladesh.

Goltens’ specialists started the work by dismantling and extracting the 80-tonne engine block from an existing power plant in a rural location in the Philippines. At this stage, visual inspection and nondestructive testing were performed to confirm suitability of the block for the project. Once ready for land transportation, the engine block was transported 50 kilometers to the port by multi-wheeler trailer. The engine block was then loaded onto a heavy lift vessel for onward transportation to Singapore.

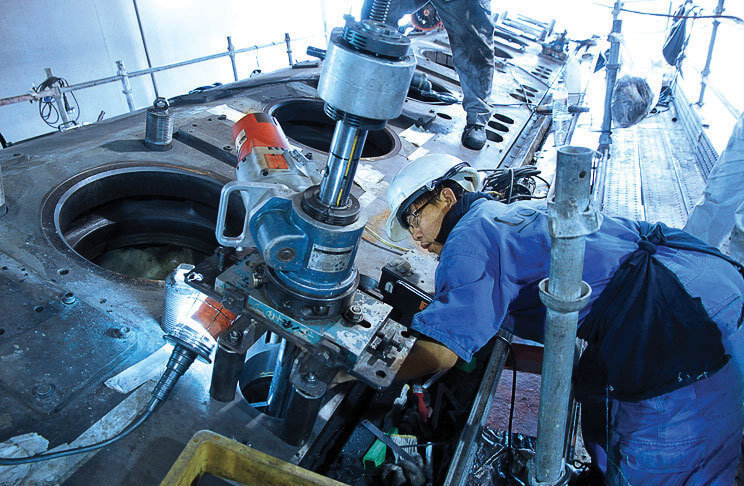

Upon arrival at the Port of Singapore, the engine block was unloaded and moved overnight to the Goltens workshop, accompanied by a police escort for increased safety. Goltens Singapore in-situ machining experts carried out the modification and conversion of the used diesel engine block into a gas-diesel engine block using specialized In-Situ Machining equipment.

PROJECT FACTS

| Engine Type: | Wartsila 18V46 |

| Bore and Stroke: | 460 / 580 mm |

| Length and weight of block: | 12.3 M / 82 MT |

| Max Power and RPM: | 18,900 KW / 514 RPM |

IN-SITU MACHINING REPAIRS CONSISTED OF

- Laser alignment and full calibration on all main bearing pockets.

- In-Situ grinding of all liner landing surfaces.

- In-Situ machining of 3 lower liner landing surfaces

- Fabrication of new bushes, shrink fitting and securing of new bushes for the lower liner landings.

- In-situ machining of all fuel pump bores to accommodate the gas fuel pump body design.

- Honing of all crankpins and main journals

- Milling counterweight contact landings

- In-Situ milling of locating key way and in-situ drilling of location pinhole for new fuel pump design.

- Full blasting and painting, under paint manufacturer supervision and procedures.

DIESEL ENGINE SERVICES PERFORMED

- Calibration and NDT performed on all liner, fuel pump and main bearing landing surfaces.

- Disassembly and relocation of replacement block to Singapore

- Disassembly of damaged engine in Bangladesh

- Reassembly of engine with reconditioned block in Bangladesh

- Final inspection and Engine commissioning

WARTSILA BLOCK REPLACEMENT RESULTS

Although the diesel and machining work performed was largely routine for Goltens, the complex logistics surrounding the project in 3 countries made it a very challenging assignment. All operational tests were successful and the engine was turned over to Covanta.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now