Laser Alignment Services

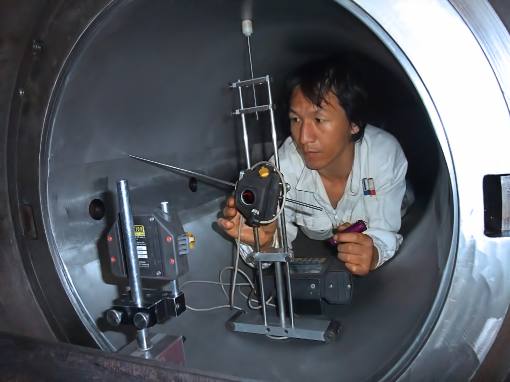

Goltens’ In-Situ technicians have broad expertise as it relates to the use of state-of-the-art laser alignment and laser scanning tools.

Goltens utilizes these tools and techniques on a daily basis in conjunction with the performance of its other In-Situ machining and retrofit design services and it is this repeated high tolerance usage that makes our technicians some of the best in the world.

Goltens also offers these services on a standalone basis to support a wide variety of troubleshooting and alignment issues encountered by customers who are diagnosing cause of failure, installing new equipment or reinstalling repaired equipment or simply suspect their equipment is out of alignment.

Whatever the application, Goltens technicians are ready wherever you need them to do the job with precision and speed.

Goltens’ Laser Alignment Advantages

- Specialized laser alignment and scanning equipment deployed at our stations around the world

- A global team of specialists who are expert in the use of the equipment to ensure a rapid response anytime and anywhere

Laser Alignment Applications

- Shaft alignment (couplings)

- Line bore measurements/center of circle

- Alignment of rotating machinery

- Alignment of stern tube bearings

- Sheave/pulley alignment

- Straightness

- Flatness

- Plumb line

Laser Scanning Applications

- 3D scanning of engine rooms for retrofit applications

- Hull surveys/scans

- 3D Dimensional checks (using laser tracker)

- Thermal growth evaluation

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert